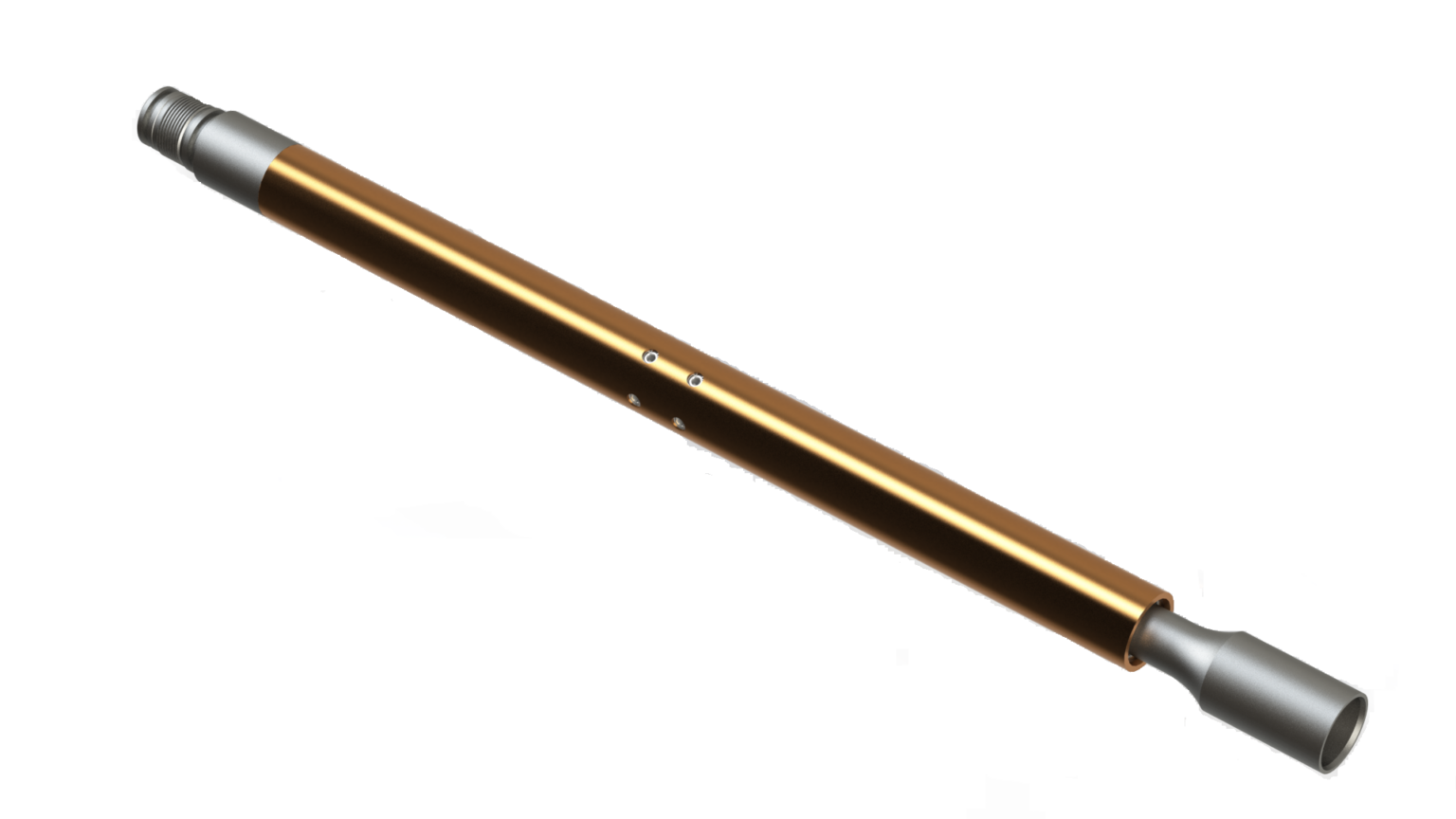

Advanced Signal Isolation & Connectivity

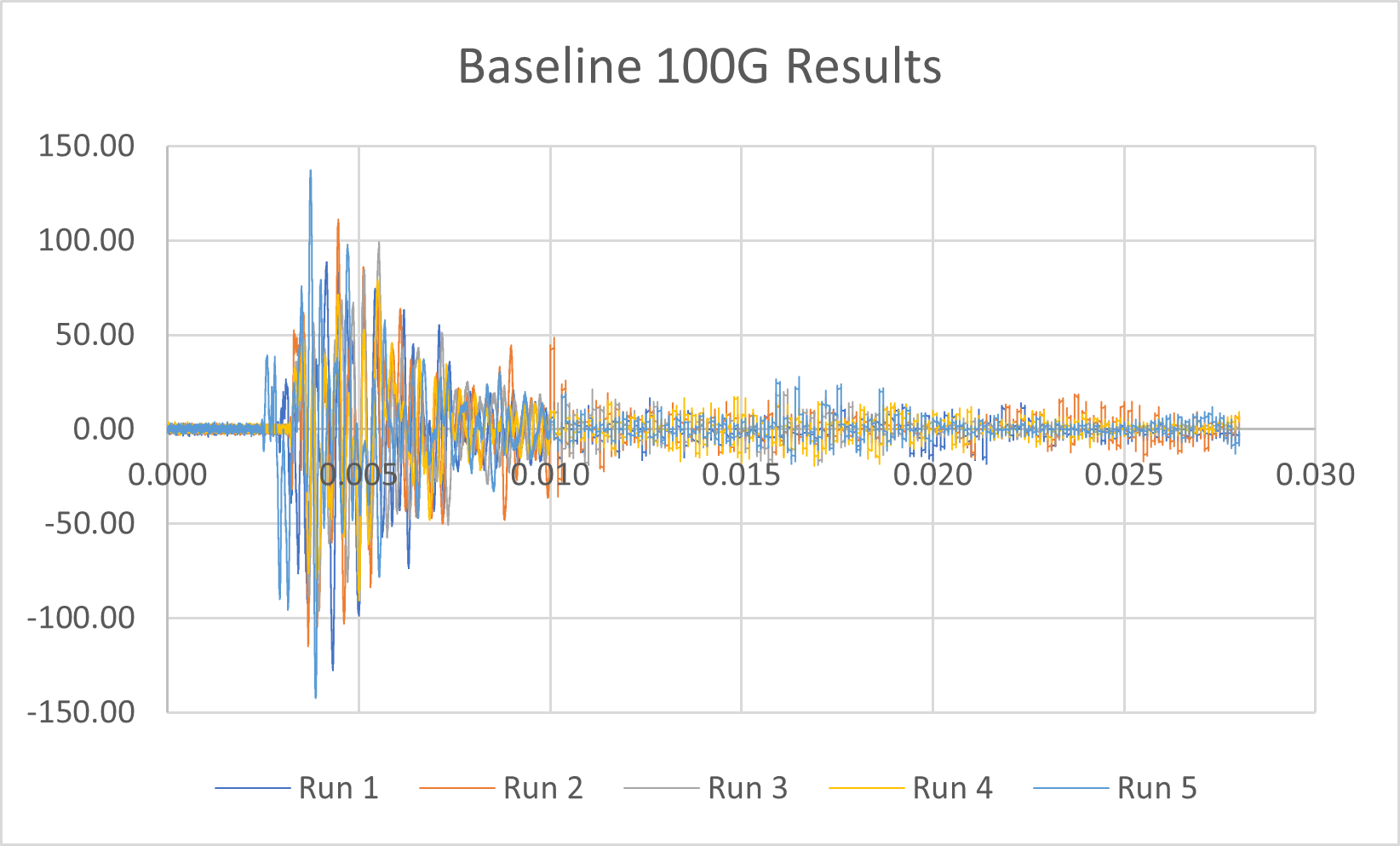

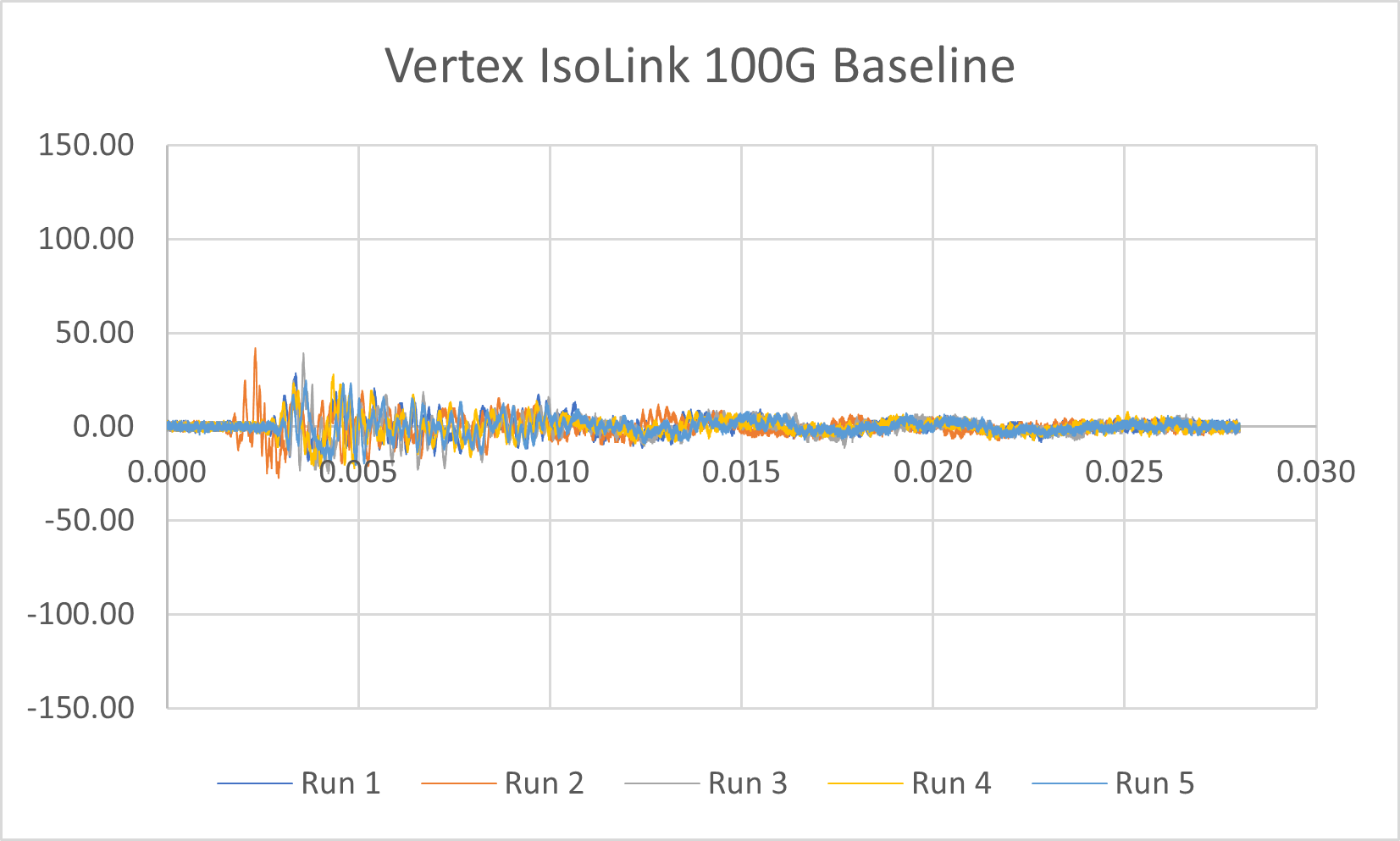

The Vertex Isolator was developed with simplicity and reliability in mind. Improving survivability of MWD equipment in harsh environments by reducing shock and impact transmission by 70%. Placed between the pulser and lower end valve the Vertex Isolator is a simple, cost-effective solution to protecting the MWD from axial drilling dysfunctions.